opening work in process inventory formula

Content Accounting Topics Inventory Type 1. However by using this formula you can get only an estimate of the work in process inventory.

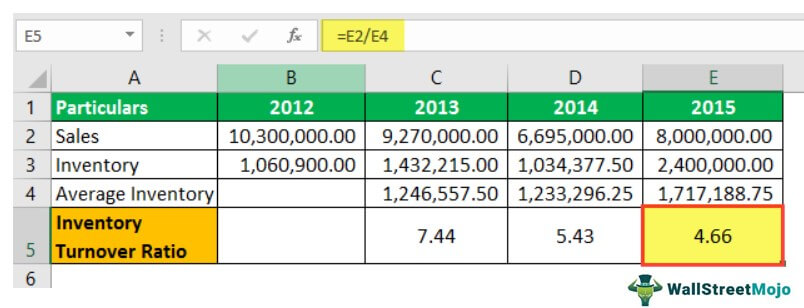

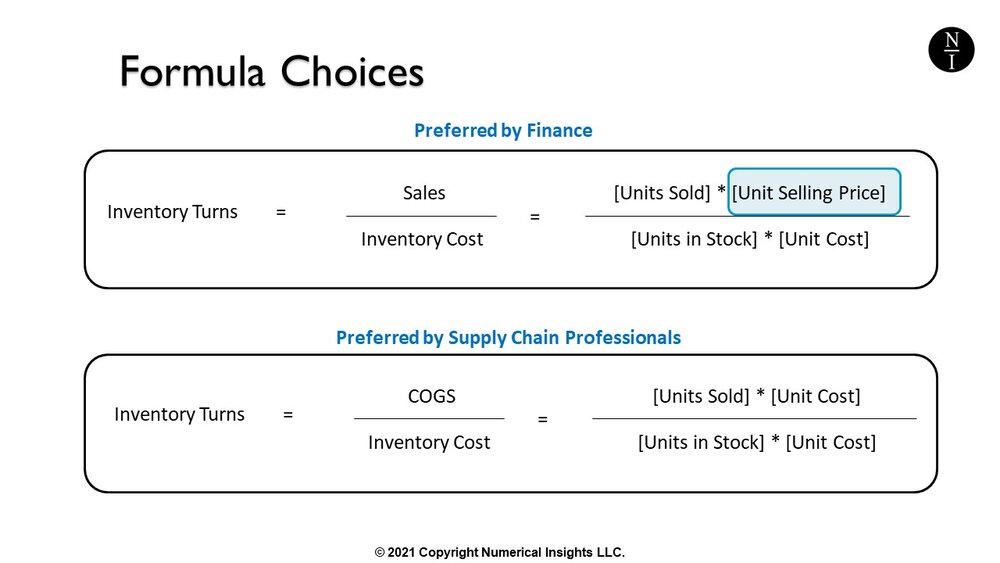

Formula To Calculate Inventory Turns Inventory Turnover Rate

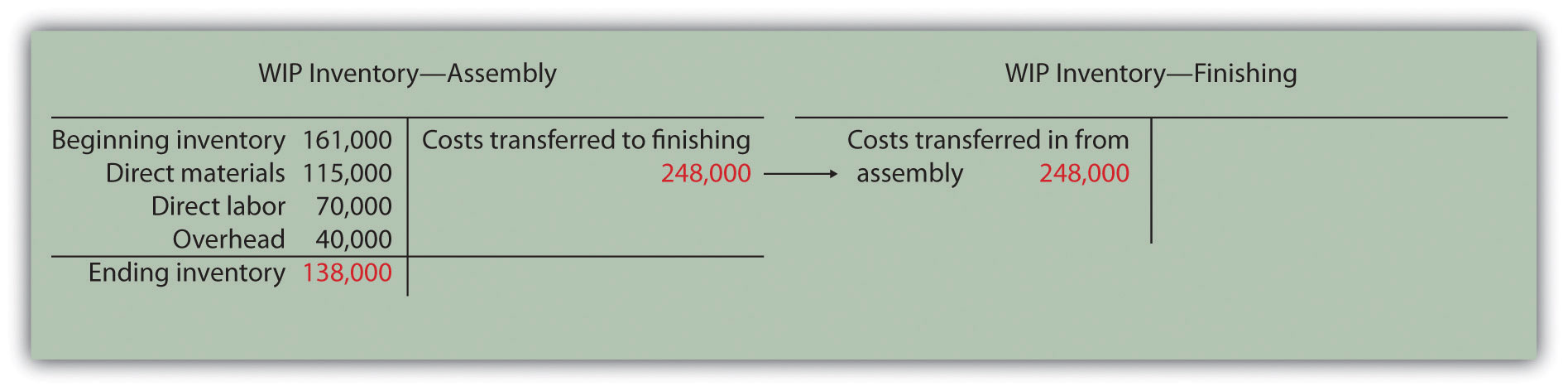

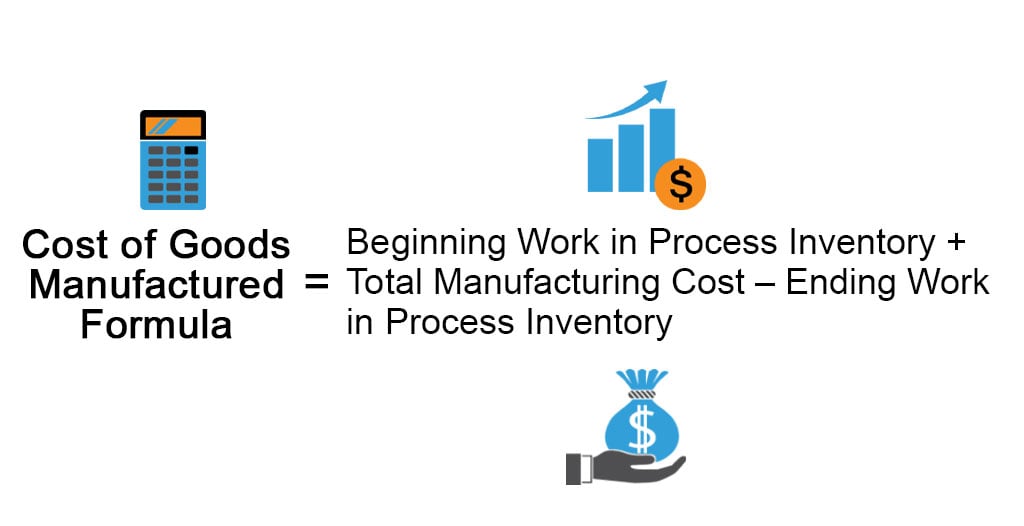

Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM.

. Total Cost of Manufacturing Beginning Work in Process Inventory Ending Work in Process Inventory Cost of Manufactured Goods. 10000 300000 250000 60000 Work in process inventory 60000. The ending WIP beginning WIP manufacturing costs - cost of goods produced This represents the value of the partially completed inventory which accounts for only a part of what the company will actually produce.

Determine the cost of goods sold COGS with the help of your previous accounting periods records. Quality Control Software SPC Charts Tools and Templates. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory Work In-process Inventory Example Assume Company A manufactures perfume.

Below is the data table. For the exact number of work in process inventory you need to calculate it manually. Work in process inventory examples.

ABC International has beginning WIP of 5000 incurs manufacturing costs of 29000 during the month and records 30000 for the cost of goods manufactured during the month. Calculating your beginning inventory can be done in four easy steps. Your WIP inventory formula would look like this.

Calculating Your Work-In-Process Inventory To calculate your in-process inventory the following WIP inventory formula is followed. The formula for calculating beginning inventory is. Opening work-in-process inventory closing work-in-process inventory cost of goods manufactured.

Therefore as per the formula 8000 240000 238000 10000 This means that Crown Industries has 10000 work in process inventory with them. Heres how youll need to do it. The WIP figure reflects only the value of those products in some intermediate production stage.

See the formula for calculating ending inventory. Another example would be one of your production equipment. After the beginning WIP inventory is determined along with the manufacturing costs and the COGM its easy to calculate the amount of WIP inventory that you currently have.

Cost of goods manufactured. 4000 Ending WIP. The work-in-process inventory account is an asset account that is used to track the cost of the partially finished goods.

Abnormal loss- Physical units produced are multiplied by the degree of completion. WIP is calculated as a sum of WIP inventory total direct labor costs and allocated overhead costs. The work in process formula is expressed as.

Work in process inventory formula in action Lets say you start the year with 10000 worth of raw materials. During the remaining financial year the company has made purchases amounting 20000 and during that time on the companys income statement the cost of goods sold is 40000. You incur 300000 in manufacturing costs and produce finished goods at a cost of 250000.

Under this method the cost of completed units is calculated by multiplying production expressed in terms of equivalent units. By simplifying the above formula we can say cost of goods manufactured is basically. How do I account for work in progress inventory.

Work in process inventory includes all raw goods production expenses and labor costs associated with producing merchandise inventory. Let say company A has an opening inventory balance of 50000 for the month of July. Abnormal gain- Physical units 100 complete.

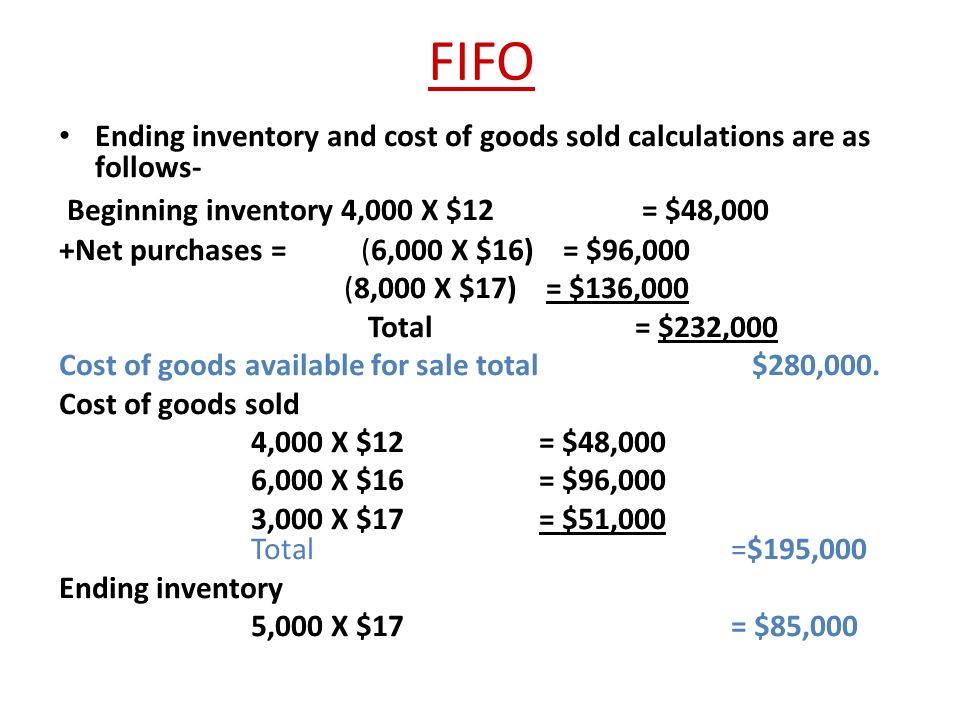

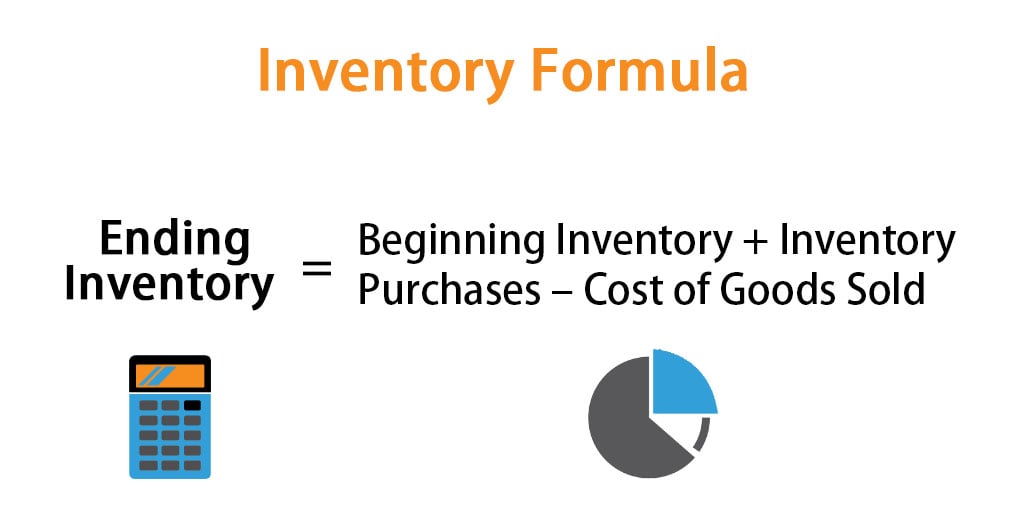

Ending inventory Previous accounting period beginning inventory Net purchases for the month COGS. Beginning WIP Inventory Manufacturing Costs Cost of Finished Goods Ending WIP Inventory If your head is spinning with all these figures dont worry. Ending inventory 800 x 2 1600.

The formula for calculating the WIP inventory is. The work in process formula is the beginning work in process amount plus manufacturing costs minus the cost of manufactured goods. An important note to consider is that work in process inventory can vary greatly.

Multiply your ending inventory balance by the production cost of each inventory item. How to calculate beginning inventory. 5000 Beginning WIP 29000 Manufacturing costs - 30000 cost of goods manufactured.

Do the same with the amount of new inventory. Ending inventory Previous accounting period beginning inventory Net purchases for the month COGS. Work in process inventory formula.

Work in Process Inventory Formula Therefore the formula from which a business can calculate their COGM using work in process inventory costs can be displayed like this. Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM. Its ending work in process is.

The work in process formula is. Inventory Formula Example 1. Work-in-Process Inventory Formula Once you know your beginning WIP inventory manufacturing costs and COGM you can start to use the WIP inventory formula.

For example you have run out of materials to create a certain amount of products. Once you have all three of these variables the formula for calculating WIP inventory is. Beginning WIP Inventory Production Costs Finished Goods Ending WIP Inventory.

Work in process inventory formula. This excludes the value of raw materials not yet incorporated into an item for sale. However by using this formula you can get only an estimate of the work in process inventory.

Once youre able to determine your beginning WIP inventory and you calculate your manufacturing costs as well as your cost of manufactured goods you can easily determine how much WIP inventory you have. In this case for example consider any manufactured goods as work in process. The beginning WIP inventory cost refers to the previous accounting periods asset section of the balance sheet.

Some inventory might have one stage of machining done and other inventory might have all but one stage of machining done. Add the ending inventory and cost of goods sold. Work in process inventory calculations should refer to the past quarter month or year.

For the exact number of work in process inventory you need to calculate it manually. Beginning Inventory Formula COGS Ending Inventory Purchases. Works in process WIP are included in the inventory line item as an asset on your balance sheet.

As a result of this you would have to freeze the production process until you have bought the materials to use. This means that Crown Industries has 10000 work in process inventory with them. Budgeted sales qty x sp.

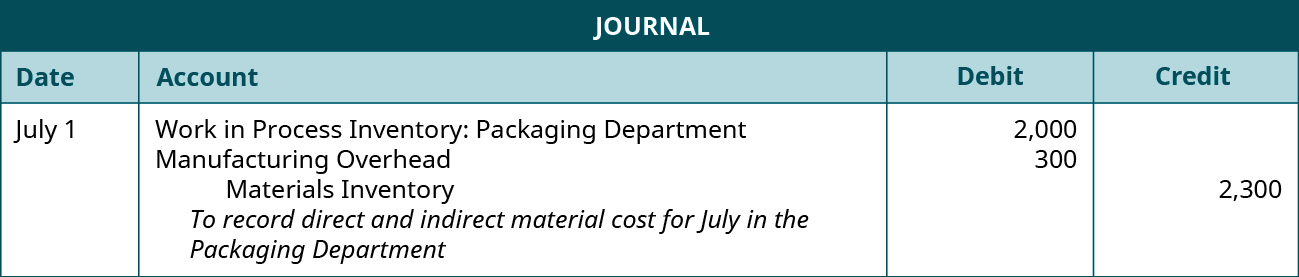

Prepare Journal Entries For A Process Costing System Principles Of Accounting Volume 2 Managerial Accounting

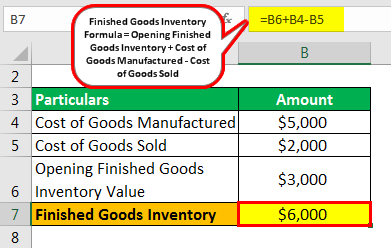

Finished Goods Inventory How To Calculate Finished Goods Inventory

How To Calculate Ending Inventory Using Absorption Costing Online Accounting

Manufacturing Account Format Double Entry Bookkeeping

How To Calculate Ending Inventory The Complete Guide Unleashed Software

Inventory Raw Materials Work In Progress And Finished Goods

How To Calculate Finished Goods Inventory

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Ending Work In Process Double Entry Bookkeeping

Inventory Formula Inventory Calculator Excel Template

Finished Goods Inventory How To Calculate Finished Goods Inventory

Wip Inventory Definition Examples Of Work In Progress Inventory

What Is Work In Process Wip Inventory How To Calculate It Ware2go

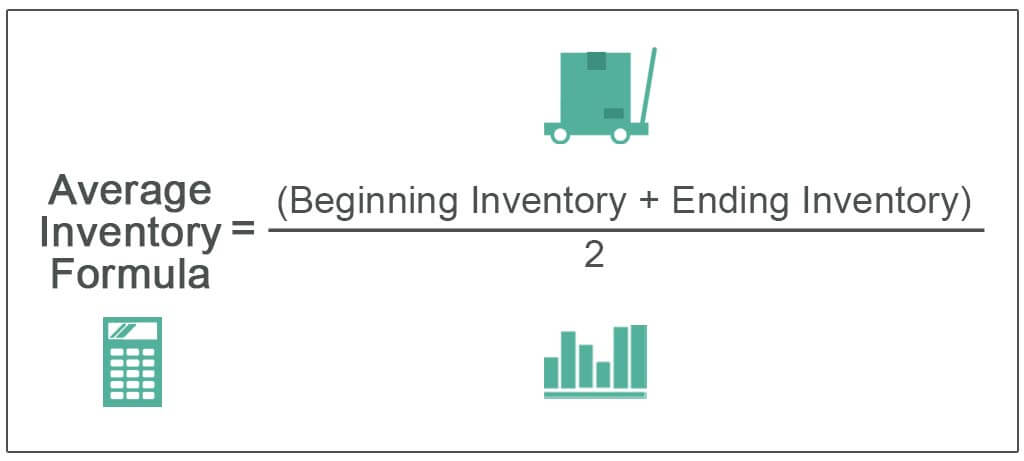

Average Inventory Formula How To Calculate With Examples

Work In Process Wip Inventory Youtube

Cost Of Goods Manufactured Formula Examples With Excel Template